Research

Area

The interdisciplinary nature of micro & nano systems has brought together

experts from many engineering research areas such as microfabrication technology,

mechanical design, material science, tribology, control theory, metrology, electrostatics,

robotics, and many science subjects such as physics, chemistry, and biology. Thus,

the research programs of the Institute are rather broad.

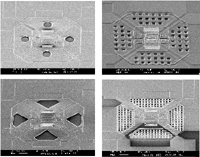

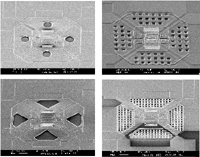

Fabrication and characterization and characterization

of micro devices & systems

Capabilities, such as deep reactive ion etching, fusion and anodic bonding

and electroplating, which are more specific to MEMS realization, will be added

to  enhance the

existing strength of the Microelectronic Fabrication Facility. These would remove

the constraint of working with limited film thickness (a few micrometers) using

conventional surface micro-machining techniques, thus allowing also the readlization

of "high-profile" devices. Others, such as advanced double-sides bond

aligner, would allow the fabrication of complicated 3-dimensional structure.

Focus will also be placed on identifying and characterizing new materials, which

might enhance MEMS performance or ease device integration by improving process

compatibility.

enhance the

existing strength of the Microelectronic Fabrication Facility. These would remove

the constraint of working with limited film thickness (a few micrometers) using

conventional surface micro-machining techniques, thus allowing also the readlization

of "high-profile" devices. Others, such as advanced double-sides bond

aligner, would allow the fabrication of complicated 3-dimensional structure.

Focus will also be placed on identifying and characterizing new materials, which

might enhance MEMS performance or ease device integration by improving process

compatibility.

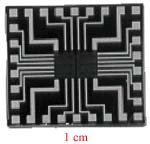

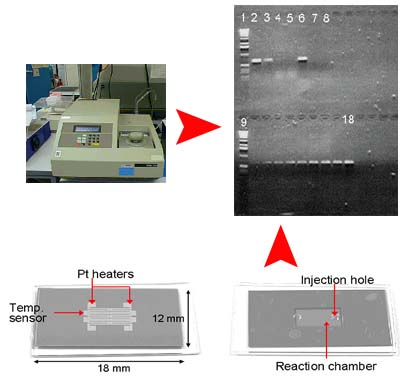

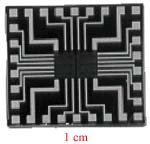

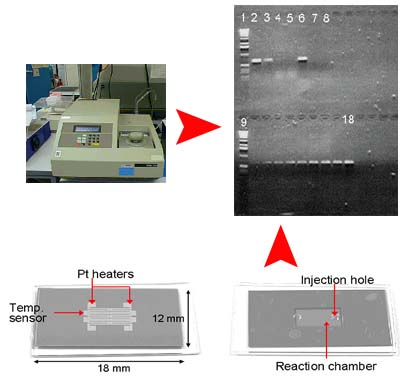

Biochips

The research activities in the area are mainly focused on the development of

the genechip and lab-on-a-chip technology as well as niche applications.  The

program aims to develop in-house fabrication capabilities for high density genechip

arrays, PCR (polymerase chain reastion) chips, and microcapillary electrophoresis

systems. Niche applications will initially target TCM, including diagnostics

(identification of toxic TCMs or adulterated TCMs) , genomics, and drug discovery.

These areas have been selected on the basis of their immediate benefits to Hong

Kong and their ptential for providing a strong foundation by which to support

and encourage local investment and entrepreneurial initiatives. It is our vision

that these resarch activities will significantly contribute to and support:

(i) the establishment of a local genechip industry, and (ii) the local development

of biotechnology and biotechnology-oriented electronics, computer hardware,

and software industries.

The

program aims to develop in-house fabrication capabilities for high density genechip

arrays, PCR (polymerase chain reastion) chips, and microcapillary electrophoresis

systems. Niche applications will initially target TCM, including diagnostics

(identification of toxic TCMs or adulterated TCMs) , genomics, and drug discovery.

These areas have been selected on the basis of their immediate benefits to Hong

Kong and their ptential for providing a strong foundation by which to support

and encourage local investment and entrepreneurial initiatives. It is our vision

that these resarch activities will significantly contribute to and support:

(i) the establishment of a local genechip industry, and (ii) the local development

of biotechnology and biotechnology-oriented electronics, computer hardware,

and software industries.

Integrated transducers

Transducer receives signal and retransmits it in a different form. Transducers

are a key components in any nano- and microsystems. Transducers find  applications

in a wide range of areas. In biological system, as the result of some biochemical

reaction a signal was detected which can be used to trigger other biochemical

reactions. This type of transducer is critically important in Smart Laboratory-on-a-chip.

In environmental applications, transducers can detect air, water and food pollution.

In personalized telecommunication, transducers can sense the location which

a user is located so that appropriate wireless communication profile can be

enabled for the user as they move from one location to another. Possible areas

of research are biological / biochemical transducers, environmental transducers,

transducers for telecommunications. In each of the proposed area we should be

able to find application in Hong Kong as well as advance the state-of-the-art

in nano- and microsystems in the world

applications

in a wide range of areas. In biological system, as the result of some biochemical

reaction a signal was detected which can be used to trigger other biochemical

reactions. This type of transducer is critically important in Smart Laboratory-on-a-chip.

In environmental applications, transducers can detect air, water and food pollution.

In personalized telecommunication, transducers can sense the location which

a user is located so that appropriate wireless communication profile can be

enabled for the user as they move from one location to another. Possible areas

of research are biological / biochemical transducers, environmental transducers,

transducers for telecommunications. In each of the proposed area we should be

able to find application in Hong Kong as well as advance the state-of-the-art

in nano- and microsystems in the world

In addition, the combination of micro-optics and integrated optics with microelectronics

and micromechanics creates a broad class of micro-opto-electro-mechanical systems

(MOEMS). Many devices for potential applications such as laser diode correctors

/ collimators, adaptive fiber couplers, hybrid refractive-diffractive color

separators, fiber optic multiplexing, micro vision and illumination, optical

micro sensors, optical modulation and laser communication will be developed.

The ultimate goal is to construct low cost, portable, compact, robust micro

optical devices to replace current bulky, touchy, expensive optical systems.

Micro &nano fluidic systems

Micro & nano thermal systems

The MEMS community is introducing a wealth of microfabricated sensors, actuators,

pumps, and microfluidic devices whose functionality relies on heat transfer.

Attempts to optimize these devices demand a comprehensive understanding of the

fundamental thermal transport phenomena occurring at short length and time scales.

The research activities in this area will focus on the systematic investigations

in two-phase flow characteristics and phase-change heat transfer mechanisms

in microchannels and porous structures having nano-scale pores. Specific topics

include: 1) Bubble dynamics in microstructures; 2) Boiling and condensation

heat transfer in microchannels; 3) Micromachined silicon inverted-meniscus evaporators;

4) Phase-change-actuated micro pumps; 5) Microscale refrigeration systems; and

6) Two-phase flow and heat transfer in micro fuel cells.

Micro & nano chemical systems

Microreactors and membrane microseparators are parts of a new paradigm in chemical

engineering process that gave birth to microchemical system technology. Through

miniaturization, new opportunities in chemical production, material manufacture

and power generation can be  exploited

to satisfy the needs of a increasingly mobile society. It has been envisioned

that a complete microchemical device such as microfuel cells, will consist of

several major components responsible for fluid delivery, reaction and separation.

A smart unit may be included to monitor, control and coordinate the performance

of each of these components. A microfuel cell with power rating less than 100

W will have an enormous market demand as power unit for most portable devices

including cellular phones and computers. Central to the realization of a microfuel

cell device is the development of new electrode, catalyst and membrane materials

that will provide more effective energy generation.

exploited

to satisfy the needs of a increasingly mobile society. It has been envisioned

that a complete microchemical device such as microfuel cells, will consist of

several major components responsible for fluid delivery, reaction and separation.

A smart unit may be included to monitor, control and coordinate the performance

of each of these components. A microfuel cell with power rating less than 100

W will have an enormous market demand as power unit for most portable devices

including cellular phones and computers. Central to the realization of a microfuel

cell device is the development of new electrode, catalyst and membrane materials

that will provide more effective energy generation.

Micro-mechanics and micro-dynamics

Some fundamental scientific issues in solid mechanics and dynamics at the micrometer

scale are under study. Three key issues will be addressed: 1) assessment of

the testing methods for measuring the mechanical properties of MEMS materials,

so as to propose standardized testing procedures; 2) analyses of the major failure

mechanisms of micro structural components (e.g. micro-beams, micro-frames, micro-springs

and membranes) by taking into account of size effect and surface effect which

significantly influence the failure modes and criteria; and 3) examination of

dynamic factors (e.g. stress waves, inertia and strain-rate sensitivity of materials)

which influence the deformation and failure of micro components under shock

or impact loads.

Novel materials for micro & nano systems

The research activities in this area are primarily focused on the charaterization

of some smart materials such as piezoelectric materials, shape memory alloys

(SMAs) and shape memory polymers (SMPs), as well as their utilization in micro

systems. For instance, prototypes of SMA thin film micro-sensors and micro-actuators

are under development. Applications of SMAs in medical macro- and micro-surgery

will also be investigated. The application of ER fluids in transmitting forces

and nano-channel ion selective membranes for chemical sensors and medical analysis

will also be studied.

enhance the

existing strength of the Microelectronic Fabrication Facility. These would remove

the constraint of working with limited film thickness (a few micrometers) using

conventional surface micro-machining techniques, thus allowing also the readlization

of "high-profile" devices. Others, such as advanced double-sides bond

aligner, would allow the fabrication of complicated 3-dimensional structure.

Focus will also be placed on identifying and characterizing new materials, which

might enhance MEMS performance or ease device integration by improving process

compatibility.

enhance the

existing strength of the Microelectronic Fabrication Facility. These would remove

the constraint of working with limited film thickness (a few micrometers) using

conventional surface micro-machining techniques, thus allowing also the readlization

of "high-profile" devices. Others, such as advanced double-sides bond

aligner, would allow the fabrication of complicated 3-dimensional structure.

Focus will also be placed on identifying and characterizing new materials, which

might enhance MEMS performance or ease device integration by improving process

compatibility.  The

program aims to develop in-house fabrication capabilities for high density genechip

arrays, PCR (polymerase chain reastion) chips, and microcapillary electrophoresis

systems. Niche applications will initially target TCM, including diagnostics

(identification of toxic TCMs or adulterated TCMs) , genomics, and drug discovery.

These areas have been selected on the basis of their immediate benefits to Hong

Kong and their ptential for providing a strong foundation by which to support

and encourage local investment and entrepreneurial initiatives. It is our vision

that these resarch activities will significantly contribute to and support:

(i) the establishment of a local genechip industry, and (ii) the local development

of biotechnology and biotechnology-oriented electronics, computer hardware,

and software industries.

The

program aims to develop in-house fabrication capabilities for high density genechip

arrays, PCR (polymerase chain reastion) chips, and microcapillary electrophoresis

systems. Niche applications will initially target TCM, including diagnostics

(identification of toxic TCMs or adulterated TCMs) , genomics, and drug discovery.

These areas have been selected on the basis of their immediate benefits to Hong

Kong and their ptential for providing a strong foundation by which to support

and encourage local investment and entrepreneurial initiatives. It is our vision

that these resarch activities will significantly contribute to and support:

(i) the establishment of a local genechip industry, and (ii) the local development

of biotechnology and biotechnology-oriented electronics, computer hardware,

and software industries. applications

in a wide range of areas. In biological system, as the result of some biochemical

reaction a signal was detected which can be used to trigger other biochemical

reactions. This type of transducer is critically important in Smart Laboratory-on-a-chip.

In environmental applications, transducers can detect air, water and food pollution.

In personalized telecommunication, transducers can sense the location which

a user is located so that appropriate wireless communication profile can be

enabled for the user as they move from one location to another. Possible areas

of research are biological / biochemical transducers, environmental transducers,

transducers for telecommunications. In each of the proposed area we should be

able to find application in Hong Kong as well as advance the state-of-the-art

in nano- and microsystems in the world

applications

in a wide range of areas. In biological system, as the result of some biochemical

reaction a signal was detected which can be used to trigger other biochemical

reactions. This type of transducer is critically important in Smart Laboratory-on-a-chip.

In environmental applications, transducers can detect air, water and food pollution.

In personalized telecommunication, transducers can sense the location which

a user is located so that appropriate wireless communication profile can be

enabled for the user as they move from one location to another. Possible areas

of research are biological / biochemical transducers, environmental transducers,

transducers for telecommunications. In each of the proposed area we should be

able to find application in Hong Kong as well as advance the state-of-the-art

in nano- and microsystems in the world exploited

to satisfy the needs of a increasingly mobile society. It has been envisioned

that a complete microchemical device such as microfuel cells, will consist of

several major components responsible for fluid delivery, reaction and separation.

A smart unit may be included to monitor, control and coordinate the performance

of each of these components. A microfuel cell with power rating less than 100

W will have an enormous market demand as power unit for most portable devices

including cellular phones and computers. Central to the realization of a microfuel

cell device is the development of new electrode, catalyst and membrane materials

that will provide more effective energy generation.

exploited

to satisfy the needs of a increasingly mobile society. It has been envisioned

that a complete microchemical device such as microfuel cells, will consist of

several major components responsible for fluid delivery, reaction and separation.

A smart unit may be included to monitor, control and coordinate the performance

of each of these components. A microfuel cell with power rating less than 100

W will have an enormous market demand as power unit for most portable devices

including cellular phones and computers. Central to the realization of a microfuel

cell device is the development of new electrode, catalyst and membrane materials

that will provide more effective energy generation.